What is Coaxial Cable?

Coaxial cables, with their unique design, are electrical cables specifically engineered to transmit high-frequency signals with minimal loss and interference. Their widespread use in telecommunications, broadcasting, and computer networking is a testament to their ability to carry signals over long distances while preserving signal integrity.

Structural of Coaxial Cable:

Inner/Center Conductor: A core wire typically constructed from copper or copper-coated steel. This component carries the electrical signals that drive our technological systems.

Dielectric Insulator: This layer separates the inner conductor from the outer layers and helps maintain signal quality by reducing signal loss. It is made from materials like polyethylene and surrounds the inner conductor.

Conducting Shield: A metallic shield, usually made of braided copper or aluminium foil, encasing the dielectric insulator, is not just a cover but a protector, blocking external electromagnetic interference (EMI) and ensuring the signal carried by the inner conductor remains undisturbed.

Protective Outer Jacket: A plastic or rubber outer sheath covers the entire cable assembly. This jacket protects the internal components from physical damage, moisture, and environmental factors.

How Coaxial Cables Transmit Signals:

Coaxial cables transmit electrical signals through the inner conductor. In contrast, the outer conductor (shield) acts as a ground reference and shields the signal from external noise. The coaxial design ensures that the electromagnetic field carrying the signal exists only in the space between the inner and outer conductors. This configuration minimises signal loss and prevents interference from external electromagnetic fields.

Signal Transmission Mechanism:

The signal is transmitted as a transverse electromagnetic (TEM) wave between the inner conductor and the outer shield in a coaxial cable. The dielectric insulator maintains the necessary separation between these conductors, allowing the signal to propagate efficiently. The uniform spacing and consistent impedance the dielectric material provides ensure that the signal experiences minimal reflection and attenuation.

Role of the Shielding in Preventing Interference:

The outer conductor or shielding is crucial in protecting the signal’s integrity. It acts as a barrier against external electromagnetic interference by absorbing and redirecting unwanted noise away from the inner conductor. This shielding ensures the signal remains clean and distortion-free, essential for high-quality data transmission.

Key Features of Coaxial Cable

- Reduced Signal Loss: The coaxial design minimises signal attenuation over long distances compared to other cable types, such as twisted pair cables.

- Superior Shielding: Effective shielding reduces the impact of external interference, making coaxial cables suitable for environments with high electromagnetic noise.

- High Bandwidth Capability: Coaxial cables can support a wide range of frequencies, making them ideal for broadband internet and high-definition television applications.

- Durability: The protective outer jacket and robust construction enhance the cable’s longevity, reducing maintenance and replacement costs.

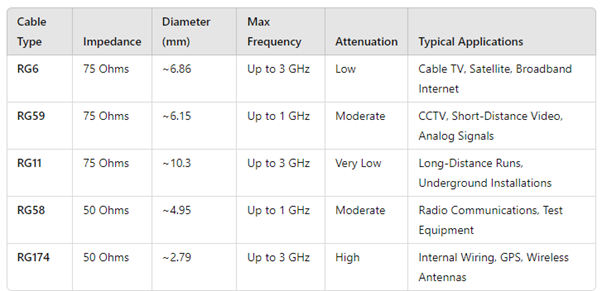

Common Types of Coaxial Cables and Applications:

Coaxial cables are available in various types, each designed to meet specific requirements regarding impedance, attenuation, frequency range, and physical characteristics.

Active Components partners with globally reputable manufacturers to provide a variety of cable types tailored to your applications. Let us know your specifications, and we can assist in sourcing the suitable cable and wire for your needs.

RG6 Characteristics:

- Impedance: 75 Ohms.

- Diameter: Approximately 6.86 mm (0.27 inches).

- Frequency Range: Up to 3 GHz.

- Construction: Features a solid copper or copper-clad steel inner conductor with a foam dielectric insulator.

- Shielding: Typically, dual or quad-shielded with layers of aluminium foil and braided aluminium.

Applications:

- Cable Television (CATV): Standard for delivering cable TV signals to homes and businesses.

- Satellite TV Systems: These connect satellite dishes to receivers due to their low signal loss at high frequencies.

- Broadband Internet: Common in connecting modems and routers for high-speed internet access.

- High-Definition Video Transmission: Suitable for transmitting HDTV signals with minimal interference.

RG59 Characteristics:

- Impedance: 75 Ohms.

- Diameter: Approximately 6.15 mm (0.24 inches).

- Frequency Range: Up to 1 GHz.

- Construction: Smaller inner conductor and dielectric compared to RG6.

- Shielding: Generally single or dual-shielded with less effective shielding than RG6.

Applications:

- Closed-Circuit Television (CCTV): Ideal for analog video and security camera systems over short distances.

- Short-Distance Video Transmission: Suitable for connecting VCRs, DVD players, and older video equipment.

- Low-Frequency Applications: Used where high frequencies are not required and cable runs are relatively short.

RG11 Characteristics:

- Impedance: 75 Ohms.

- Diameter: Approximately 10.3 mm (0.41 inches).

- Frequency Range: Up to 3 GHz.

- Construction: Larger inner conductor and thicker dielectric insulation than RG6.

- Shielding: Enhanced shielding for superior signal integrity over long distances.

Applications:

- Long-Distance Signal Transmission: Ideal for cable runs exceeding 100 feet where signal loss needs to be minimised.

- Outdoor and Underground Installations: Suitable for harsh environments due to its robust construction.

- Main Distribution Lines: Used in backbone networks for cable TV and high-speed internet services.

RG58 Characteristics:

- Impedance: 50 Ohms.

- Diameter: Approximately 4.95 mm (0.195 inches).

- Frequency Range: Up to 1 GHz.

- Construction: Features a stranded or solid inner conductor with a polyethylene dielectric.

- Shielding: Single braided shield.

Applications:

- Radio Communications: Common in amateur radio, CB radio, and low-power RF connections.

- Laboratory and Test Equipment: Used for signal connections in testing environments.

- Ethernet Networking (Legacy Systems): Utilised in older 10Base2 networks.

RG174 Characteristics:

- Impedance: 50 Ohms.

- Diameter: Approximately 2.79 mm (0.11 inches).

- Frequency Range: Up to 3 GHz.

- Construction: Very thin and highly flexible, with a stranded inner conductor.

Applications:

- Internal Device Wiring: Used within devices where space is limited.

- GPS and Antenna Connections: Suitable for connecting small antennas in GPS units and wireless systems.

- RF Communication Equipment: Ideal for short connections in RF circuits.

Factors to Consider When Choosing a Coaxial Cable

Selecting the appropriate coaxial cable for your specific application is crucial to ensuring optimal performance, signal integrity, and system longevity. Several factors need to be considered:

Impedance Compatibility

Impedance Compatibility directly affects signal transmission efficiency and system performance. Impedance, measured in Ohms (Ω), represents the resistance to the flow of alternating current (AC) in a circuit. The most common coaxial cable impedances are 50Ω and 75Ω, each suited to specific applications based on their electrical characteristics.

Typically, 75Ω cables are used in television, satellite, and broadband applications. Examples include RG6, RG59, and RG11 cables, designed to carry high-frequency signals with minimal loss, making them ideal for delivering clear audio and video.

On the other hand, 50Ω cables are standard in radio communications, professional audio, and data networking environments. Cables like RG58 and RG174 fall into this category. They are engineered to handle RF transmission and data signal requirements.

By selecting a coaxial cable with the appropriate impedance, you align the electrical properties of your cabling with those of your devices, thereby preventing inefficiencies and ensuring a reliable and high-quality signal transmission throughout your system.

Frequency Range and Bandwidth

The coaxial cable must support your system’s specific frequency range to ensure efficient and reliable signal transmission. Higher-frequency signals are more likely to lose strength over distance, so cables with lower attenuation characteristics are needed to maintain signal integrity.

Additionally, applications that transmit large amounts of data or high-definition video require cables with higher bandwidth capabilities. Using a cable that can handle the necessary bandwidth ensures that signal quality is preserved, preventing data loss and performance degradation.

Signal Attenuation

Attenuation refers to the gradual loss of signal strength as it travels through the cable. Thus, signal attenuation directly impacts the quality of the transmitted signal over long distances.

For longer distances, cables like RG11 are preferred because they have lower attenuation than other coaxial cables, meaning they lose less signal over the same distance.

Environmental Conditions

Indoor

Standard cables with essential protective jackets are typically sufficient for indoor applications. They are designed to perform well in controlled environments with minimal factors like moisture and extreme temperatures.

Outdoor

However, for outdoor installations, the cable needs to be more robust. Outdoor coaxial cables must be equipped with UV-resistant and weatherproof jackets to withstand exposure to sunlight, moisture, and fluctuating temperatures. These cables are designed to endure the harsh conditions of outdoor use, ensuring longevity and consistent signal quality.

Underground

Additional protection is necessary in cases where cables will be installed underground. Cables used in underground installations should have moisture-resistant jackets and, ideally, be rated for direct burial. It ensures they can withstand exposure to the elements, including water and soil, without degrading over time, which helps maintain signal integrity and reduces the need for maintenance.

Physical Flexibility

When considering the physical flexibility and durability of cables, it’s important to ensure they can withstand the specific demands of your application. For scenarios involving frequent movement or tight bending, such as robotics or portable equipment, cables with high flexibility are crucial. These typically feature stranded conductors, allowing the cable to bend and move without compromising its structural integrity.

Another key factor is the bending radius. Every cable has a minimum bending radius that should not be exceeded, as doing so can lead to damage or reduced performance. Cables not properly chosen for their environment may experience breaks or signal degradation if bent too sharply during installation or use. Thinner and more flexible wires, such as RG174, are easier to bend and fit into confined areas, making them ideal for installations where space is limited, or the cable needs to follow complex paths. Their flexibility also makes them suitable for applications with movable equipment, reducing the risk of damage from constant movement.

In environments exposed to mechanical stress, choosing cables equipped with reinforced jackets or armour is essential. These features provide an extra layer of protection against abrasion, impact, or other physical wear and tear, ensuring the cables remain functional even in harsh conditions.

Shielding Needs

Shielding effectiveness is another critical factor ensuring cables maintain signal integrity, especially in electromagnetic interference (EMI) environments. The level of shielding in a cable directly influences its ability to reject external EMI and prevent signal leakage, both of which are vital for maintaining the reliability of data transmission and minimising disruptions.

Cables with single shielding are typically used in environments with minimal EMI. This basic layer of protection is sufficient for applications where interference is not a major concern, such as in residential or low-noise commercial settings. However, single shielding may not provide enough protection for areas exposed to more substantial interference, such as industrial environments or locations with numerous electronic devices.

Dual or quad shielding is often required in high-interference areas, offering enhanced protection against EMI. Dual shielding, which usually involves a combination of foil and braid layers, provides a robust defence against external noise, ensuring signals remain clear and consistent even in challenging conditions. Quad shielding furthers this protection by adding additional layers, making it suitable for extremely high-interference environments where maintaining signal integrity is critical.

In some cases, a combination of foil and braid shielding offers superior protection across a wide frequency range. This combination provides excellent shielding efficiency by blocking high-frequency and low-frequency interference, making it ideal for applications that demand the highest levels of signal integrity. The foil layer is a barrier against high-frequency noise, while the braid offers effective shielding against lower-frequency interference, resulting in comprehensive EMI protection for the cable.

Manufacturer Reputation and Support

Purchasing cables from manufacturers with a strong reputation for consistent quality and reliability gives you confidence that the product will meet industry standards and perform effectively in your specific applications. Well-established manufacturers typically have stringent quality assurance processes, ensuring that each cable produced undergoes thorough testing to meet performance specifications. This attention to detail can significantly reduce the risk of premature failure, performance degradation, or compatibility issues.

Reputable manufacturers or suppliers provide comprehensive technical assistance to guide customers through selecting the most appropriate cable. This support can be invaluable, especially when dealing with complex installations or unique requirements that demand expert advice. Whether you need help understanding specifications, configuring custom solutions, or troubleshooting issues post-installation, A reputable supplier with solid customer service can help streamline the process and reduce downtime.

Moreover, suppliers that offer ongoing support will likely stay updated with the latest technological advancements and industry standards, ensuring that the products they supply are current and compatible with evolving technologies. This ensures that customers not only purchase a reliable product but also gain access to expert knowledge and assistance throughout the lifecycle of their cable installations.

Why choose Active Components?

- Extensive Industry Experience: With over 41 years in the electronics component industry and project experience, we possess deep knowledge across various projects, enabling us to deliver high-quality, reliable custom cable assemblies.

- Collaboration with Global Manufacturers: We collaborate closely with leading global cable assembly and wire harness manufacturers to customise components like connectors and cable accessories to meet specific customer requirements.

- Inventory Management and Stock Availability: We provide inventory management services from our warehouses, with options to hold stock in New Zealand and Hong Kong. This ensures that our customers can quickly respond to spikes in demand or plan against demand forecasts.